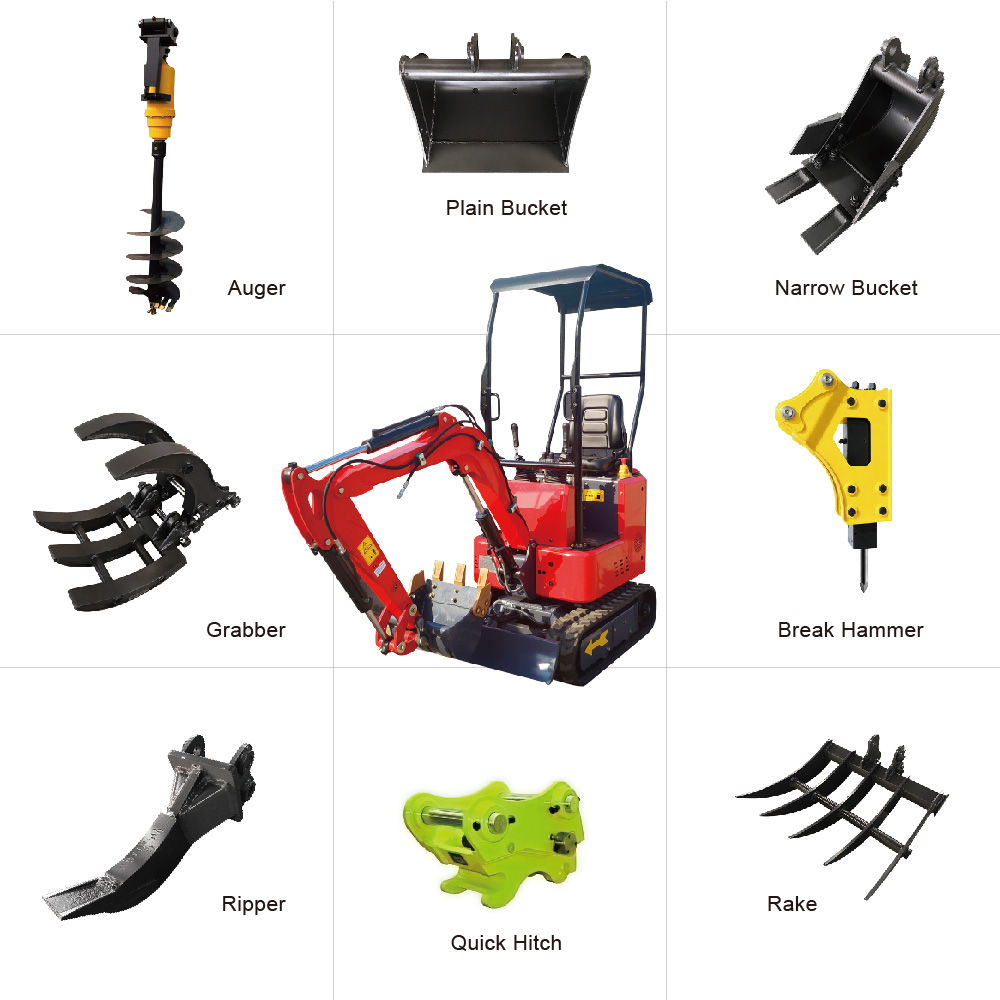

Excavator Accessories

Excavator Accessories advantage

Reliable quality

Strong fit

Functional excellence

Cost effective

Perfect after-sales guarantee

Reliable quality: high-quality excavator accessories are usually made of high-strength and wear-resistant metal materials, such as bucket teeth using special alloy steel, heat treatment process, hardness and toughness, can withstand the huge impact and friction in the excavation operation, the service life is significantly longer than ordinary accessories, reduce the frequency of replacement, to ensure the continuous and stable operation of equipment.

Strong adaptability: Designed and developed for specific types of excavators, the size, interface and installation method of various accessories are accurately matched, and the installation process is convenient and smooth, without complicated modification. For example, the diameter and joint specifications of the hydraulic tubing fit perfectly with the excavator hydraulic system to ensure the stable transmission of hydraulic oil and the best work efficiency.

Functional excellence: Some advanced accessories have unique functions to enhance the overall performance of the excavator. For example, intelligent monitoring system accessories can real-time monitor engine oil temperature, oil pressure, working hours and other key parameters, early warning of potential failures, easy to timely maintenance, reduce the risk of sudden equipment failure; High-performance filters can filter impurities more effectively, protect core components such as engines and hydraulic systems, and extend the service life of equipment.

High cost efficiency: In the long run, although the procurement cost of high-quality parts may be slightly higher, due to strong durability and low failure rate, maintenance costs and downtime can be greatly reduced. Reduced downtime means increased operational efficiency, more economic benefits, and lower overall costs.

Perfect after-sales protection: accessories produced by regular manufacturers generally provide perfect after-sales. Cover product quality assurance, technical consultation, return and exchange services. In the use of problems, users can get timely professional guidance and solutions, no worries.

The mini excavator is fitted with a narrow bucket with teeth to enhance the digging and gripping power, which can effectively grab loose materials for accurate digging. It can also be used to handle harder materials such as frozen soil. The teeth on the narrow bucket with teeth can be embedded into the gap or surface of hard materials like wedges, with the excavator's digging action, using the teeth's cutting force and the prying action of the bucket body, gradually breaking up and digging up the hard materials, which is more conducive to coping with this kind of high-intensity, high-hardness digging tasks compared with the ordinary flat bucket.

In all kinds of earthmoving projects, such as site leveling in construction sites, roadbed filling in road construction, etc., the flat bucket installed in the excavator can shovel up loose soil, sand and gravel and other earth materials over a large area, and then load them into the transportation vehicle quickly and smoothly. Its flat bottom and large opening design are conducive to the gathering and transferring of materials, which can effectively improve the loading efficiency and guarantee the smooth progress of earthmoving projects. Advancement.

The mini excavator is installed with sand hopper, which can screen and classify materials. Separate coarse and fine materials and eliminate impurities. For example, in some old site cleaning, demolition site excavated materials may be mixed with wood, plastic debris and other impurities, the sieve hopper can be based on the set size of the sieve holes, the size does not match the impurities sieve away, leaving the requirements of the available materials to enhance the purity of the material, which will help to better reuse or dispose of excavated materials.

4.Rake

The mini excavator is installed with a rake, which can be used for debris cleaning, garbage sorting, grass collection. River cleaning and other operations. In the forest, after logging, wind damage and other situations, there will be a lot of branches, fallen leaves, broken wood and other debris left on the ground, which not only affects the aesthetics, but also may harbor pests, hinder the planting of new saplings, and so on. The rake on the excavator can go deep into the forest and rake these debris together, so that it can be conveniently and uniformly transported out of the forest area for treatment and maintenance of environmental health in the forest area.

The installation of grab clips on excavators can significantly expand their functionality and application scenarios. Grippers can be used for material picking and loading, block material handling, rubbish removal, picking up bricks and concrete and timber after demolition of buildings, and in agriculture and forestry operations, they can easily pick up the stalks of sugarcane, reeds and other plants, which is convenient and reduces the intensity of manual labour.

Hightop Mini Excavator is capable of breaking up hard soil and loosening slumped ground when fitted with a looser. When digging into hard or compacted soil, digging directly with the bucket will face greater resistance, which not only slows down the digging speed, but also increases the energy consumption and mechanical wear and tear of the excavator. After the soil is loosened in advance by the looseners, the resistance of the bucket when digging will be greatly reduced, so that the digging operation can be completed more quickly and the overall work efficiency can be improved.

One Machine, multi-usage.Quick and easy replacement of accessories

1. Narrow bucket: 200mm wide, suitable for digging narrow trenches

2. Rake:

3. Ripper:

4. Plane bucket: width 500mm, 800mm, or other sizes, without gears, suitable for leveling the ground

5. Grabber: Grab wood, sugarcane, etc.

6. Quick Hitch: Quickly connect various attachments

7. Auger: consists of three parts: drilling rig, bracket and drill pipe

200mm wide and 700mm long, drilling depth: 800-900mm

8. Title bucket: It can shovel any angle of the ditch wall and level the inclined surface. Shihe slope plane repair, river, ditch and other dredging work.

Width 600mm, tilt angle 30°

9. Thumb bucket

10. Break hammer:

11. Grasp the steel clamp

12. Trimming machine: Cropper

13.Pile driver

14.Trailer

Narrow bucket 200mm | Bucket width:200mm( 8″) Package size: 570mm*280mm*390mm |

Narrow bucket 260mm | Bucket width:260mm( 10.5″) |

Plain bucket 500mm | Bucket width:500mm( 20″) Package size: 570mm*420mm*390mm |

Plain bucket 600mm | Bucket width:600mm (24″) Package size:700mm*420mm*390mm |

Plain bucket 800mm | Bucket width:800mm (32″) Package size:920mm*420mm*390mm |

Plain bucket 1000mm | Bucket width:1000mm(39.5″) Package size:1100mm*420mm*390mm |

Plain bucket 1200mm | Bucket width:(47.5″) Package size:1320mm*420mm*390mm |

Sieve bucket 600mm | Bucket width:600mm(24″) |

Sieve bucket 800mm | Bucket width:800mm (32″) |

Rake Dimensions | 490*530mm |

Rake weight | 11.15kg |

Grapple weight | 25.95kg |

Ripper Dimensions | 480*50*88mm |