1000kg Mini Excavator HT10C

Complete research and development test system each excavator must undergo more than 2000 hours of field excavation force test.

Core components such as working device, cab and hydraulic components must undergo more than 800,000 anti-fatigue tests.

HIGH STANDARDS OF QUALITY VERIFICATION

HIGHTOP USES double standards of ISO and CE to ensure that every machine is up to standard.

FIRST-CLASS CONFIGURATION

1. Dynamical System

High quality KOOP Euro 5/EPA/ Kubota engine can ensure the reliability of the machine under bad working conditions.

Come with red flexible coupling that acts as a shock absorber. If the engine jumps or the different shafts act, this will compensate.

2. Oil Supply System

lubricating oil pressure alarm system for protect the machine, it will be alarm automatically if no lubricating oil.

Equipped with high precision air filter and oil filter, the filtration accuracy is up to 1 micron, the filtration rate is more than 99.9%.

The hydraulic tank breathing valve has a pressure compensating valve and air filtering function. The other manufacturers' machines are only one cover, no pressure.

The entrance of the hydraulic oil tank is equipped with magnets to prevent tiny objects such as rust from entering the hydraulic oil tank

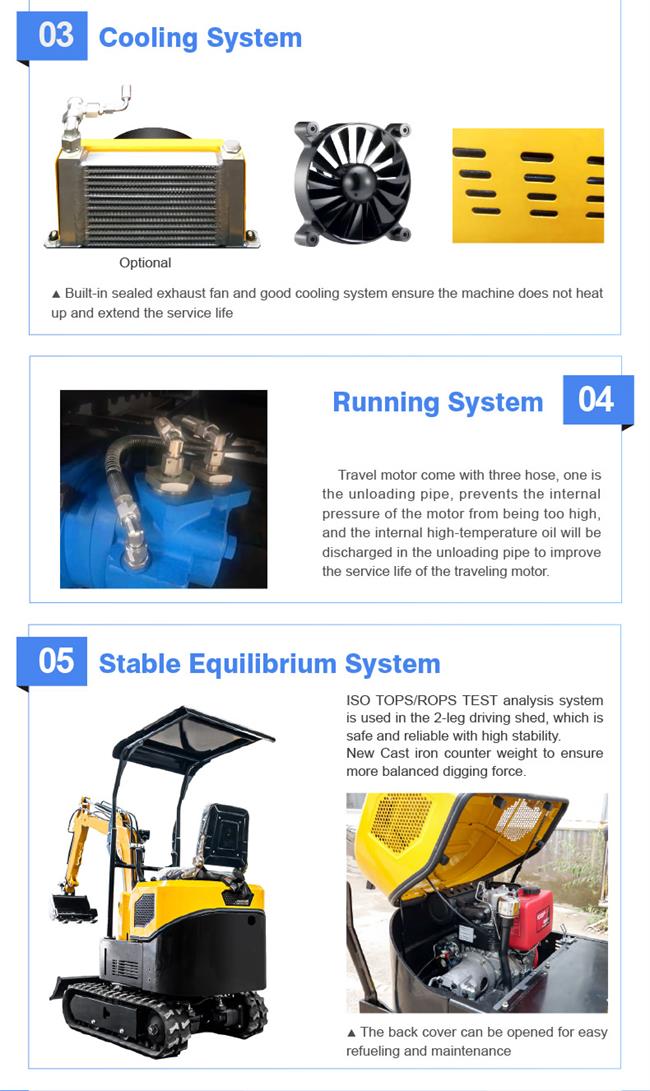

3. Cooling System

Built-in sealed exhaust fan and good cooling system ensure the machine does not heat up and extend the service life.

4. Running System

Travel motor come with three hose, one is the unloading pipe, prevents the internal pressure of the motor from being too high, and the internal high-temperature oil will be discharged in the unloading pipe to improve the service life of the traveling motor.

5. Stable Equilibrium System

ISO TOPS/ROPS TEST analysis system is used in the 2-leg driving shed, which is safe and reliable with high stability.

New Cast iron counter weight to ensure more balanced digging force.

The back cover can be opened for easy refueling and maintenance

6. Security System

The key has the waterproof function, avoids to cause the power short circuit at the rainy day.

Safety seat is equipped with a seat belt that is mobile and more comfortable.

High strength German imported hydraulic pipeline, withstand higher pressure.

Using high strength bolts 4.9 and 8.8, other manufacturers are use white 4.8 bolts.

Beautiful Rubber Joystick.

7. Shock Mitigation System

Increase the rubber cushion, the engine shock absorption effect is more obvious.

8. Load Sensitive System

With the original SLSS hydraulic system, the perfect match between engine and main pump can be realized, and the output power of engine can be maximized to improve operation efficiency.

Actuating arm deflection and auxiliary pipeline adopt full hydraulic control, and the operation is more accurate and efficient.

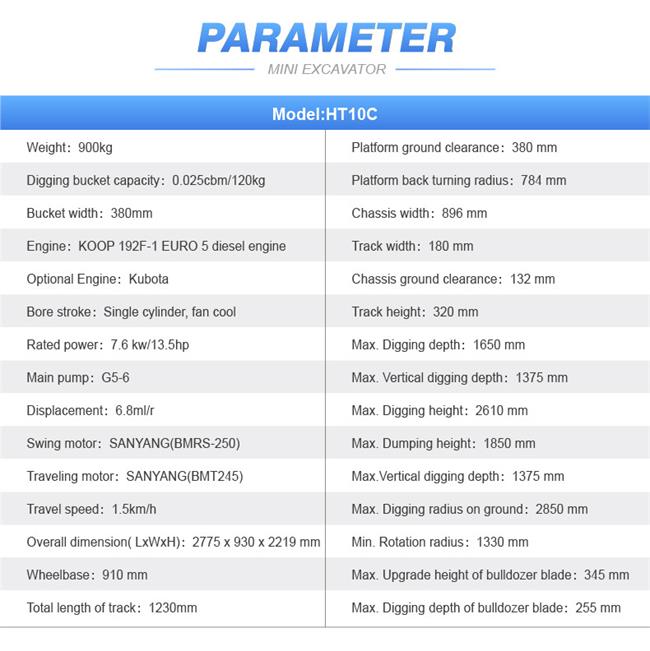

Weight | 1000kg |

Bucket width | 380mm |

Digging bucket capacity | 0. 025cbm/120kg |

Engine | KOOP 192F-1 EURO 5 diesel engine |

Optional Engine | Kubota |

Bore stroke | Single cylinder, fan cool |

Rated power | 7.6 kw/13.5hp |

Main pump | G5-6 |

Displacement | 6 8ml/r |

Swing motor | SANYANG(BMRS -250) |

Traveling motor | SANYANG(BMT245) |

Travel speed | 1.5km/h |

Overall dimension( L xWxH) | 2775x 930 x 2219mm |

Wheelbase | 910 mm |

Total length of track | 1230mm |

Platform ground clearance | 380 mm |

Chassis width | 896 mm |

Platform back turning radius | 784 mm |

Track width | 180 mm |

Chassis ground clearance | 132 mm |

Track height | 320 mm |

Max. Digging depth | 1650 mm |

Max. Vertical digging depth | 1375 mm |

Max. Digging height | 2610 mm |

Max. Dumping height | 1850 mm |

Max. Vertical digging depth | 1375 mm |

Max. Digging radius on ground | 2850 mm |

Min. Rotation radius | 1330 mm |

Max. Upgrade height of bulldozer blade | 345|mm |

Max. Digging depth of bulldozer blade | 255mm |